Project

Westlink was engaged to provide a multimodal logistics solution for twenty-six (26) pipe rack modules fabricated in Tianjin, China to be used in the construction of a new polyisobutylene (PIB) unit at the Lubrizol Deer Park Facility in Houston, USA.

-

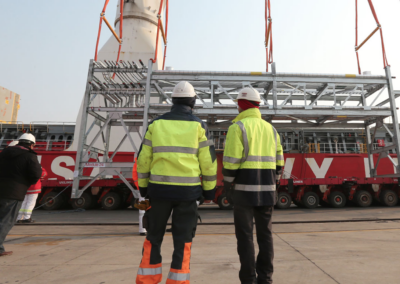

SPMT – fabrication yard to vessel hook at Lingang

-

Heavy Lift Vessel (HLV) – Lingang, Tianjin to Industrial Terminals, Houston

-

SPMT – vessel hook to laydown at Industrial Terminals, Houston

-

SPMT, tug and barge RORO operations – Industrial Terminals, Houston to Spilman Island laydown

-

Heavy Haulage – from Spilman Island laydown to Lubrizol Deer Park Project site

-

Zero LTIs

-

32,000 cubic metres (cbm) transported with heaviest lift 70 metric ton (mt)

-

‘Flying Deck’ configuration used on HLV to maximise stow

-

Custom spreader and rigging arrangement for each pipe rack for true vertical lifts

-

Transport of modules through busy Houston Industrial Area

-

Traffic control in Houston – police escorts, temporary removal of traffic lights, street signs and lifting of overhead lines

-

Maximum module envelope – 36 x 9.5 x 8.5 metres