WHAT WE DO

MODULARISATION

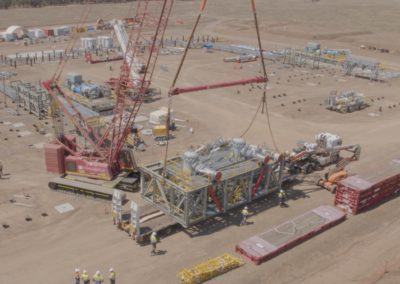

Our modular and preassembly strategies optimise cost and delivery

Westlink has been involved in transportation of modules and preassemblies for nearly thirty (30) years delivering to projects across the globe from domestic and international fabrication yards.

From huge material handling plant fabrications used in construction of iron ore mine processing facilities, to Pre Assembled Racks (PARs) that support pipe to build LNG trains, to Pre Assembled Units (PAUs) for chemical process in petrochemical plants and precast sections for major infrastructure upgrades – Westlink understands how to deliver these heavy oversized fabrications.

Westlink’s early involvement in modular/preassembly strategies can help Customers win work through savings and optimisation and minimise risk of overrun during execution.

Many major project learnings that adopt modularisation strategies reflect that logistics input into early design phases as critical to optimise degree of modularisation and constructability. Our teams work with our Customers in the front end of project feasibility and design to help determine whether a modular or stick built strategy is optimal and how to best execute either strategy’s required logistics.

Modularisation & Preassembly Specific Logistics

– Stick build versus modular construction strategies

– Maximum module envelope determination

– Fabrication yard assessments – duties, logistics, cleanliness

and others

– Maximum utilisation planning for transport assets

– Module staging and construction sequenced delivery

– Customised lifting gear design and fabrication

– Traffic management – urban areas, remote destination and onsite

– Project Management – from concept to commissioning

– Fabrication yard and construction site coordination